Container Chassis Guide: Types, Selection, and Intermodal Maintenance

The efficiency of intermodal transport relies heavily on one critical component: the container chassis. This definitive guide equips logistics managers, fleet owners, and procurement specialists with the essential knowledge needed to select the right chassis, understand all available types, and implement a robust maintenance strategy to maximize vehicle uptime and significantly minimize operational costs.

The Critical Link: Mastering Container Chassis for Intermodal Efficiency

In the world of global trade and supply chain management, intermodal logistics—the seamless movement of cargo containers across truck, rail, and sea—is the backbone of efficiency. At the final leg of this complex journey, the container chassis serves as the vital link between the terminal and the final destination. A suboptimal chassis choice or a lapse in maintenance can be the difference between a profitable delivery and a costly delay.

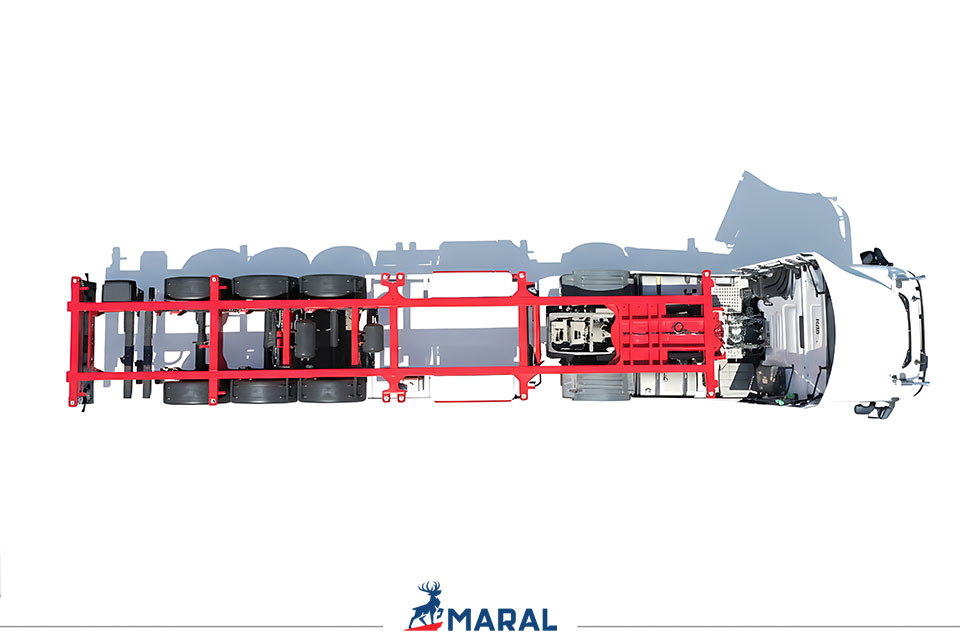

For industry leaders like Maral Sanat Javid, designing and manufacturing robust, high-performance chassis is about ensuring the reliability of your entire logistics chain. This comprehensive guide details the essential chassis types and provides a framework for preventative maintenance that will drive operational excellence.

Understanding the Core Chassis Types for Every Cargo Need

Selecting the right chassis is paramount for legal compliance, cargo safety, and cost management. Different containers and freight weights require specialized equipment. Here are the primary types of container chassis used in intermodal transport:

1. Standard (Fixed-Length) Chassis

The workhorse of the industry, the standard chassis is designed for basic, single-container transport.

- Key Use Case: Transporting standard 20-foot (20’) or 40-foot (40’) ISO dry containers.

- Benefits: Cost-effective, simple to operate, and widely available.

- Limitation: Lack of flexibility for varying container sizes or heavy/oversized loads.

2. Extendable (Sliding) Chassis

Also known as a slider chassis, this type offers essential flexibility by allowing the chassis length to be mechanically adjusted.

- Key Use Case: Hauling 20’, 40’, and 45’ containers, including dual 20’ loads, high-cube containers, or when weight distribution needs adjustment for road limits.

- Benefits: Versatility, improved weight distribution, and compliance with varying bridge and axle weight laws.

- Maral Sanat Javid Focus: Our extendable chassis models are engineered with high-strength steel and precision sliding mechanisms for reliable performance under heavy load cycles.

3. Gooseneck Chassis (Drop Frame)

The gooseneck design features a lowered floor section, accommodating taller containers while keeping the overall road height within legal limits.

- Key Use Case: Essential for transporting 40-foot and 45-foot High-Cube (HC) containers.

- Benefits: Prevents costly over-height violations, offers a lower center of gravity for improved stability and safety.

4. Specialty Chassis (Tri-Axle and Tank)

- Tri-Axle Chassis: Designed with three axles to handle significantly higher Gross Vehicle Weight (GVW) limits, crucial for dense cargo or regions with stringent weight regulations.

- Tank Chassis: Specialized skeletal frames built exclusively to carry ISO tank containers (for liquid bulk) securely, featuring reinforced twist locks and specific safety features.

While container chassis are specialized for intermodal transport, understanding other heavy-duty trailers is also key for versatile logistics. For a deeper dive into general freight hauling, explore our comparison: Flatbed vs. Lowboy Trailers: Which One Do You Need?

Choosing the Right Chassis: A 3-Point Selection Strategy

Fleet managers must conduct a thorough assessment before making a procurement decision. Focus on these three critical factors:

Cargo and Route Profile

- Container Size & Type: Are you primarily moving 20’ dry boxes (Standard chassis) or 45’ High-Cubes (Gooseneck or Extendable)?

- Weight: If your cargo pushes the legal weight limits, a Tri-Axle chassis is non-negotiable for compliance and safety.

- Regulatory Compliance: Review the axle weight laws for all jurisdictions along your route. An extendable chassis can often provide the required flexibility.

Durability and Build Quality

- Materials: Prioritize chassis built from high-grade, resilient steel to withstand the stresses of continuous loading and high road speeds.

- Corrosion Resistance: For operations near ports or in high-humidity climates, features like sandblasting and protective epoxy coatings (standard in Maral Sanat Javid products) are crucial for longevity.

Maintenance Access and Parts Availability

Choose a manufacturer with an extensive aftermarket service network. Easy access to genuine, high-quality spare parts (like those provided by Maral Sanat Javid’s service centers) drastically reduces vehicle downtime.

Maximize Uptime: Essential Container Chassis Maintenance Protocols

Downtime due to equipment failure is a major cost driver in logistics. A proactive, rigorous maintenance schedule is the simplest way to secure your profit margins.

Critical Inspection Points for Chassis Longevity

A robust preventative maintenance (PM) program should focus on these key areas:

|

Component |

Inspection Frequency |

Action Plan |

|

Brakes and Air System |

Pre-trip & 90-day PM |

Check for leaks, pad wear, and proper slack adjuster function. Ensure DOT compliance. |

|

Tires and Wheels |

Daily/Pre-trip |

Maintain correct inflation pressure (a major cause of blowouts), check tread depth, and look for signs of uneven wear. |

|

Structural Frame & Cross Members |

Weekly Visual Check |

Inspect for cracks, warping, or major dents, especially around high-stress areas like the suspension and twist lock mounts. Rust treatment is critical. |

|

Twist Locks (Securing Devices) |

Daily/Pre-trip |

Verify all locking pins and mechanisms are fully operational and not jammed or seized. This is paramount for cargo security. |

|

Suspension System |

90-day PM |

Lubricate moving parts (springs/air bags), check for loose U-bolts, and inspect axles for alignment issues. |

|

Lighting and Electrical |

Pre-trip |

Test all brake, turn, and marker lights. Replace faulty wiring or lenses immediately to ensure road legality. |

The Importance of High-Quality Spare Parts

Using subpar replacement parts can compromise the structural integrity and performance of even the best-designed chassis. Maral Sanat Javid emphasizes the use of certified, tested components in its manufacturing and after-sales service. Investing in genuine parts ensures:

- Guaranteed Fit and Performance: Components designed to meet the original chassis specifications.

- Enhanced Safety: Critical parts like brakes and suspension are certified to withstand the intended load.

- Reduced Long-Term Costs: High-quality parts last longer, reducing the frequency of repairs and labor costs.

Conclusion: The Maral Sanat Javid Commitment to Logistics Excellence

In the high-stakes environment of intermodal logistics, the container chassis is a strategic asset, not just a piece of equipment. By understanding the types available and committing to stringent, planned maintenance, fleet managers can significantly enhance safety, reduce operating expenses, and improve on-time delivery performance.

Maral Sanat Javid is committed to powering this efficiency. As a leading manufacturer, we provide a full range of high-quality, durable chassis—from robust standard models to flexible extendable designs—backed by unparalleled engineering and comprehensive after-sales support to keep your critical equipment on the road.

Faq

Top Articles

Modern Technologies Revolutionizing Trailer Axle Manufacturing

Modern trailer performance relies on advanced axles. We explore innovations in axle production that enhance fuel economy, reduce maintenance, and ensure superior road safety.

Brake Battle: Disc vs. Drum

Compare Disc Brakes vs Drum Brakes for heavy-duty vehicles. Understand pros, cons, and impact on performance, safety.

Your Ultimate Guide to Trailer Axle Types and Technical Specs

Trailer axles are the unsung heroes of heavy-duty transportation, directly impacting safety, load capacity, and operational efficiency. Choosing the wrong axle type can lead to costly downtime and compromised performance.