Commercial Trailer Guide: Choose, Buy & Maintain for Peak Business Performance

Maximize your fleet's efficiency! This comprehensive guide covers everything from choosing the ideal commercial trailer to financing options, crucial maintenance, and regulatory compliance for long-term success.

The Ultimate Guide to Commercial Trailers: From Selection to Maintenance

A commercial trailer is a significant investment and a vital asset for any business that moves goods. The right trailer improves efficiency, safety, and profitability, while a poorly chosen or maintained one can lead to costly downtime and regulatory fines. This in-depth guide provides everything you need to know, from making the right purchase decision to implementing a robust maintenance plan.

Part 1: In-Depth Trailer Selection

Choosing the right commercial trailer goes beyond just size. It's about matching the equipment to your specific operational needs and understanding the intricate details that affect performance, safety, and profitability.

1. Understanding Trailer Types and Their Applications

Dry Van Trailers: The most common trailer on the road, dry vans are the workhorses of the trucking industry. They are ideal for palletized goods, boxes, and any freight that needs protection from weather and theft. Modern dry vans are often built with lightweight aluminum for fuel efficiency or a mix of steel and composite materials for enhanced durability and impact resistance.

Refrigerated Trailers (Reefers): These trailers are essential for any business transporting temperature-sensitive cargo. They are equipped with advanced insulation and a powerful refrigeration unit (often called a "reefer unit"). The key is their ability to maintain precise temperatures, ranging from sub-zero for frozen goods to slightly cool for produce or pharmaceuticals.

Flatbed Trailers: Designed for heavy or oversized loads that are not sensitive to weather. Flatbeds are perfect for hauling construction materials, machinery, large pipes, and vehicles.

Lowbed and Drop-Deck Trailers: These are specialized flatbeds used for oversized or extremely tall cargo.

- Drop-Deck Trailers (also known as step-decks) have a deck that drops down after the front section, allowing you to haul taller loads than a standard flatbed without exceeding height limits.

- Lowbed Trailers have a much lower center of gravity and are specifically designed for hauling exceptionally heavy equipment, like excavators, bulldozers, or large industrial machinery.

Other Specialized Trailers

- Gooseneck Trailers: Known for their exceptional stability and weight distribution, these trailers are ideal for heavy-duty towing. The gooseneck hitch places the weight directly over the truck's rear axle, providing superior control.

- Tanker Trailers: Engineered for hauling liquids, gasses, or dry bulk materials like flour or cement. They are built with specific safety and structural requirements to prevent leaks and spills.

- Dump Trailers: Feature a hydraulic system that lifts the front of the trailer to "dump" bulk materials like gravel, sand, or demolition debris. Their design is focused on heavy-duty construction and reliable dumping mechanisms.

2. Weight and Capacity: Beyond the Basics

Understanding a trailer's weight ratings is crucial for safety, compliance, and preventing costly fines.

- Gross Vehicle Weight Rating (GVWR): This is the absolute maximum a trailer is designed to weigh when fully loaded, including the trailer's own weight and its cargo. Never exceed this limit.

- Gross Axle Weight Rating (GAWR): This indicates the maximum weight a single axle assembly can support. It's a critical rating for ensuring that the cargo's weight is distributed evenly across the trailer's axles, which is a key factor in vehicle stability.

- Payload Capacity: This is the actual amount of cargo a trailer can legally carry. To calculate it, you subtract the trailer's tare weight (its empty weight) from its GVWR.

- Gross Combined Weight Rating (GCWR): This is a total weight rating that includes the weight of the truck (tractor), the trailer, and the cargo. Exceeding the GCWR can strain the entire vehicle's powertrain and braking system.

- Practical Tip: Always consider the tare weight of a trailer when selecting one. A lighter trailer (e.g., aluminum construction) has a lower tare weight, which means it can carry a heavier payload and potentially improve your fuel efficiency.

3. Key Features and Components

Having understood the importance of suspension in vehicles, it’s now time to look deeper. Below, we’ll break down the key features that define suspension performance, and then move into the main components that make up these systems.

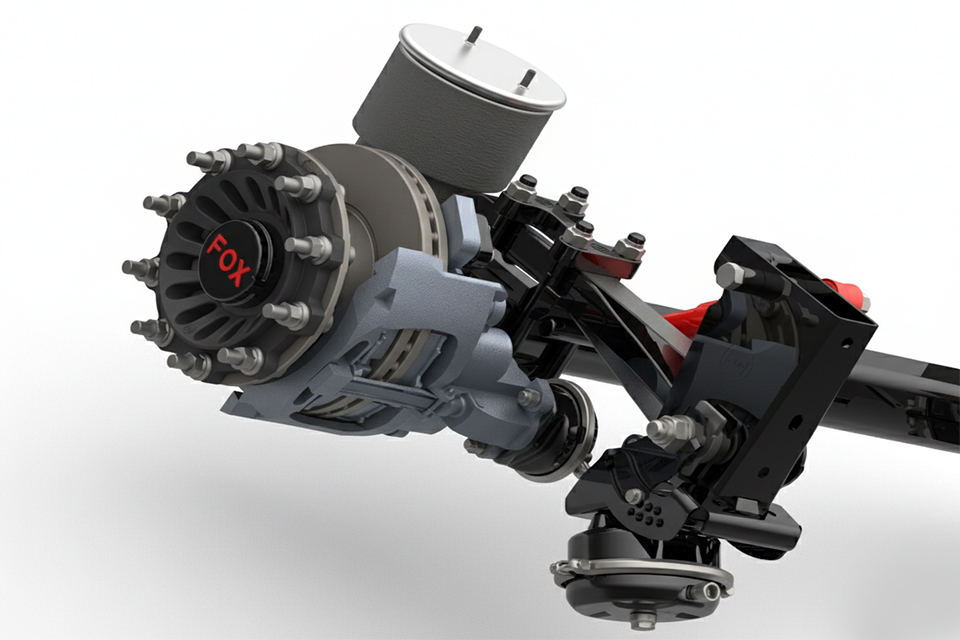

Suspension Systems

- Spring Suspension: A more traditional, rugged, and cost-effective system. It's durable and reliable for heavy, non-delicate loads.

- Air-Ride Suspension: Provides a much smoother ride, which is vital for protecting fragile cargo like electronics, glass, or perishable goods. Air-ride systems can also be adjusted (e.g., "dumping air") to lower the trailer's height, making loading and unloading easier.

- Braking Systems: Modern trailers are equipped with a range of safety features. The most critical is the Anti-lock Braking System (ABS), which prevents the wheels from locking up during hard braking, allowing the driver to maintain steering control. Proper maintenance of the brake drums, shoes, and air lines is essential for system reliability.

Doors

- Roll-Up Doors: Ideal for tight loading dock spaces, as they don't require external clearance to open. However, they can be less durable and offer a lower level of security.

- Swing Doors: More robust and secure, but they require a wide clearance at the loading dock, which can be a limiting factor.

Other Essential Components

- Flooring: Trailers come with various flooring options. Wood flooring is a common and versatile choice, while aluminum or composite flooring is lighter and resistant to water damage.

- Landing Gear: The landing gear is what supports the trailer when it is unhooked from the truck. Choosing a unit with durable, easy-to-crank landing gear is crucial for efficient operations.

- Lighting: The switch from traditional incandescent bulbs to LED lighting has become a standard. LEDs are more durable, have a longer lifespan, and draw less power from the truck's battery.

Ready to find the perfect commercial trailer for your business? Our team of experts is here to help. Contact us today for a free consultation and personalized quote. We'll help you navigate the options and make a smart investmen

Part 2: The Purchase Process and Financing

Making the decision to buy a new or used trailer involves more than just the price tag.

1. New vs. Used: A Detailed Comparison

- Buying New: You get the latest technology, a full warranty, and a clean slate. This means fewer unexpected maintenance costs. However, the initial capital outlay is much higher, and the trailer will depreciate quickly.

- Buying Used: The most appealing factor is the lower price, which frees up capital for other business needs. However, a used trailer comes with a history. Always get a pre-purchase inspection from a trusted mechanic. Check for rust, frame damage, tire wear, and a complete maintenance log.

2. Financing and Insurance

- Financing: Most dealers offer financing options, and many businesses also turn to commercial loans or leasing. Leasing a trailer can be a good option for businesses that want a predictable monthly payment and the flexibility to upgrade after the lease term.

- Insurance: Adequate commercial trailer insurance is non-negotiable. It protects your investment against theft, damage, and liability. Be sure to understand your policy's coverage limits and deductibles.

Part 3: Comprehensive Maintenance and Care

A proactive maintenance schedule is the single most effective way to extend your trailer's lifespan and avoid costly breakdowns.

1. The Pre-Trip Inspection: Your Daily Routine

Never skip this. A thorough walk-around inspection takes just a few minutes and can save you thousands.

- Tires and Wheels: Check tire pressure, tread depth, and for any signs of uneven wear, cuts, or bulges. Make sure lug nuts are tightened.

- Lights: Test all running lights, brake lights, turn signals, and hazard lights.

- Brakes: Inspect brake lines, air hoses, and test the air brake system for leaks.

- Coupling: Ensure the fifth wheel is securely locked and the safety chains or cables are attached correctly.

2. Essential Maintenance Checks

- Lubrication: Regularly grease the fifth wheel, suspension components, and wheel bearings to reduce friction and prevent premature wear.

- Brake Servicing: Have the brake shoes, drums, and air chambers inspected regularly to ensure optimal performance.

- Electrical System: Check and clean all wiring harnesses and connections. Corrosion can cause short circuits and light failures.

- Structural Integrity: Inspect the frame, crossmembers, and landing gear for any signs of rust, cracks, or damage.

Part 4: Legal and Regulatory Compliance

Operating a commercial trailer requires adherence to federal and state regulations.

- Federal Motor Carrier Safety Regulations (FMCSRs): Be aware of regulations regarding vehicle inspections, driver hours of service, and load securement.

- Annual Inspections: Most jurisdictions require commercial trailers to undergo a yearly safety inspection. Keep your inspection report and any necessary decals up-to-date.

- Licensing and Registration: Ensure your trailer is properly registered and licensed in accordance with the laws of your state or province.

Final Thoughts

A commercial trailer is a long-term investment. By making an informed decision during the selection process and committing to a rigorous maintenance schedule, you can ensure your trailer remains a safe, reliable, and profitable asset for your business for years to come.

Faq

Top Articles

Modern Technologies Revolutionizing Trailer Axle Manufacturing

Modern trailer performance relies on advanced axles. We explore innovations in axle production that enhance fuel economy, reduce maintenance, and ensure superior road safety.

Brake Battle: Disc vs. Drum

Compare Disc Brakes vs Drum Brakes for heavy-duty vehicles. Understand pros, cons, and impact on performance, safety.

Your Ultimate Guide to Trailer Axle Types and Technical Specs

Trailer axles are the unsung heroes of heavy-duty transportation, directly impacting safety, load capacity, and operational efficiency. Choosing the wrong axle type can lead to costly downtime and compromised performance.