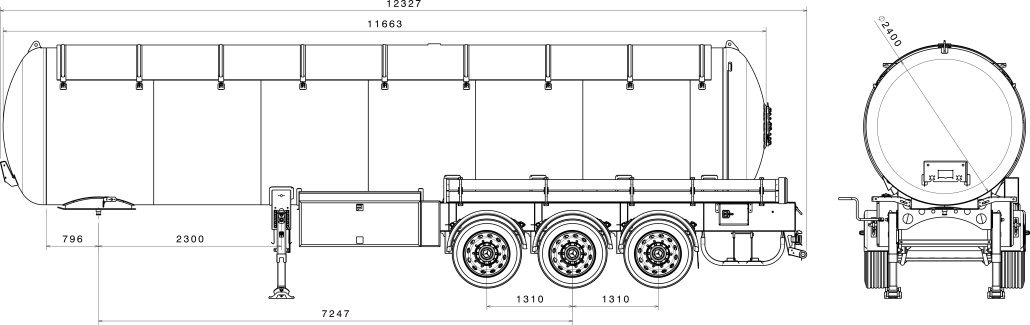

MRL LPG3 -gas tanker

Engineered for optimal safety and efficiency, our three-axle gooseneck LPG tanker trailer is designed to transport liquefied gas with maximum stability.

Three-Axle Gooseneck LPG Tanker Trailer: Standard, Safe, and Robust

Engineered with precision and built with high-quality materials, the three-axle gooseneck LPG tanker trailer adheres to all international standards to ensure maximum safety in the most demanding conditions. Its key features, including exceptional durability, advanced safety systems, and a specialized structure, make this trailer an essential asset in the energy supply chain.

Why is a Gooseneck LPG Tanker Trailer a Necessity?

Transporting flammable materials like LPG requires equipment that can withstand pressure, temperature, and potential impacts. A substandard tanker can lead to catastrophic accidents. The gooseneck LPG tanker trailer, with a body structure made from high-strength steel like P460NL2 and P355NL2 (European standard) or A516Gr70 (American standard), offers unmatched resistance to pressure and corrosion.

If your business requires the transport of other flammable liquids like gasoline or diesel, we recommend using a fuel tanker trailer specifically designed for that purpose.

Engineered for Maximum Safety

The gooseneck design of this trailer ensures optimal weight distribution, significantly increasing its stability, especially on uneven roads and sharp turns. This critical feature minimizes the risk of rollovers and provides a safer driving experience. Additionally, the three-axle configuration allows for the transport of heavier loads while putting less stress on the road and axles.

Quality control is paramount in the production of these tankers. Our manufacturing process includes the highest level of quality assurance at every stage:

- Rigorous Chemical and Mechanical Testing: All raw steel sheets undergo chemical and mechanical analysis before production to ensure their quality and strength.

- Comprehensive Visual Inspection: Visual checks are performed at various production stages—from material intake to final assembly—to identify and correct any cosmetic or structural flaws.

- Standardized Welding and Dimensions: All welds are meticulously controlled based on certified welding standards. Precise dimensional control is maintained throughout production to ensure the final product perfectly matches the design.

- Non-Destructive and Hydrostatic Testing: To guarantee the tank's integrity, it undergoes hydrostatic, liquid penetrant, ultrasonic, and radiographic tests. These tests detect any hidden cracks or defects, preventing potential future accidents.

Key Advantages

- Higher Payload: The three-axle structure allows the trailer to carry a larger volume of liquefied gas per trip, increasing efficiency and reducing the number of required journeys.

- Lower Operating Costs: Due to its high durability and minimal maintenance needs, the overall cost of ownership is significantly reduced.

Applications of the Three-Axle LPG Tanker

The primary use of the gooseneck LPG tanker trailer is the safe and secure transport of liquefied petroleum gas (LPG). This product is specifically designed to meet the needs of companies in the hazardous materials transport sector, as well as factories and refineries.

Key applications include

- Transport from Refineries to Distribution Centers: These trailers play a vital role in the fuel supply chain, moving LPG from production facilities to main storage depots and then to distribution stations.

- Fueling Industrial Facilities: Many industries, such as petrochemicals, steel production, and manufacturing, rely on LPG for their processes. These tankers are used to supply the necessary gas to these facilities.

- Commercial and Residential Distribution: Tanker trailers are used to transport LPG to distribution centers for filling the large tanks of commercial businesses and residential complexes.

- Part of Fuel Distribution Fleets: Companies specializing in the distribution of LPG use these trailers as a core part of their fleet to carry out transport operations with the highest level of safety and efficiency.

In short, wherever large volumes of LPG need to be transported, this high-quality, safety-focused tanker is the best choice.

How to Use Your Tanker Optimally

- Adhere to Capacity Limits: Never load more than the tank's maximum authorized capacity. Overloading is not only dangerous but also puts unnecessary stress on the chassis, axles, and tires, reducing their lifespan.

- Ensure a Level Surface: When loading or unloading, make sure the trailer is on a flat and level surface. This helps ensure even weight distribution and prevents concentrated stress points.

- Use Safety Equipment: Always use standard, approved equipment for connecting and disconnecting hoses and valves. Make sure all valves and connections are completely sealed before beginning your journey.

- Specialized Maintenance: For any major repairs or maintenance, use only authorized service centers. They have a complete understanding of the trailer's structure and parts.

- Genuine Spare Parts: Only use genuine spare parts approved by the manufacturer. Non-genuine parts can compromise the trailer's performance and safety and lead to costly breakdowns.

A Final Word

The three-axle gooseneck LPG tanker trailer is more than just a vehicle; it's a guarantee of safety, efficiency, and durability. By investing in this trailer, you are securing a safe and sustainable future for your business.

For more information or expert consultation, please contact our sales team.