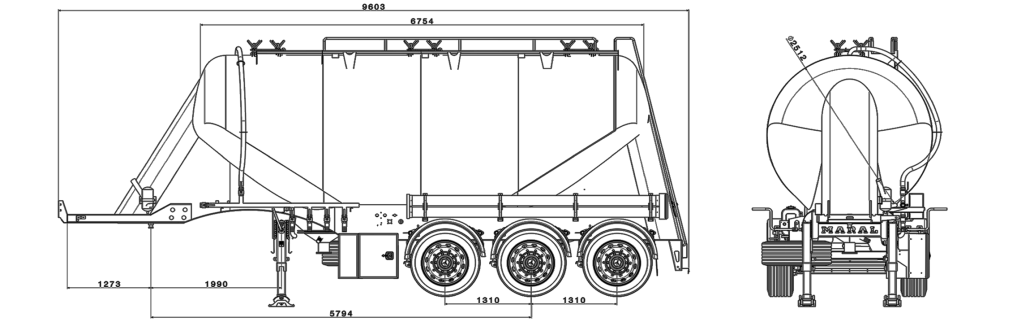

MRL BN3 - bulker

Discover Maral Sanat Javid's new generation of 3-axle cement bulk trailers. Featuring high-strength steel, a lightweight design, and an advanced pneumatic discharge system for maximum efficiency and safety in bulk transport.

New Generation 3-Axle Cement Bulk Trailer: Leading the Way in Specialized Transport

The new generation 3-axle cement bulk trailer from Maral Sanat is a modern solution for the growing demands of the construction industry. With its advanced design and cutting-edge technology, this product redefines the standards for transporting powdered materials. From cement and lime to other building materials, this bulk trailer offers flawless performance and high capacity, making it an indispensable tool for civil and construction projects.

Why a New Generation Bulk Trailer is an Investment in the Future

In today's competitive world, speed, accuracy, and reliability in transport are critical to a project's success. A high-quality bulk trailer minimizes loading and unloading times and prevents waste and contamination. The new generation 3-axle bulk trailer from Maral Sanat features a durable steel tank and a pressurized discharge system, allowing for fast and seamless cement unloading. This feature eliminates the need for manual intervention and reduces operational costs.

With its exceptional road stability, this trailer is a smart choice for transporting raw materials to remote and hard-to-reach project sites. This product, along with the 3-axle flatbed semi-trailer from Maral Sanat, which is designed for heavy and bulky loads, can complete your logistics chain.

Key Features of the Cement Bulk Trailer

- Increased Capacity and Efficiency: The tank is designed to maximize loading capacity while keeping the weight as low as possible. The 3-axle structure also ensures better weight distribution and increased stability, allowing you to carry more cement on every trip.

- Durable and Lightweight Body: The bulk trailer body is made from high-strength steel. This material guarantees resistance to corrosion and wear while keeping the overall weight low.

- Optimized Discharge System: The pneumatic (air-pressure) discharge system is fully optimized to unload cement in the shortest possible time with minimal residue. This system prevents material waste and speeds up operations.

- Advanced Suspension and Braking System: The new generation bulk trailer is equipped with a powerful suspension system that absorbs road shocks, contributing to greater stability. Furthermore, the modern EBS braking system ensures the highest level of safety.

Advantages of Using the New Generation Cement Bulk Trailer

Reduced Operational Costs: Higher efficiency per trip and reduced unloading time lead to lower fuel and labor costs.

Enhanced Safety: The robust design and advanced braking systems minimize the risk of road accidents.

Long Service Life: The use of high-quality materials and protective coatings significantly increases the bulk trailer's service life.

High Versatility: These bulk trailers are also capable of transporting various bulk powdered materials like lime powder, stone powder, and other similar substances.

Applications of the Bulk Trailer

The new generation 3-axle cement bulk trailer is an ideal choice for:

- Cement production companies

- Ready-mix concrete plants

- Large construction companies

- Civil engineering and road construction projects

This product, by offering a combination of efficiency, safety, and durability, is a wise investment for any business involved in the transport of bulk materials.

Final Word

The new generation 3-axle cement bulk trailer is more than just a vehicle; it's a smart investment in efficiency, safety, and durability. By leveraging modern design and technology, this bulk trailer helps you reduce operational costs and significantly boost your business's productivity.

For more information and to inquire about the price of a cement bulk tanker, please contact our consultants.