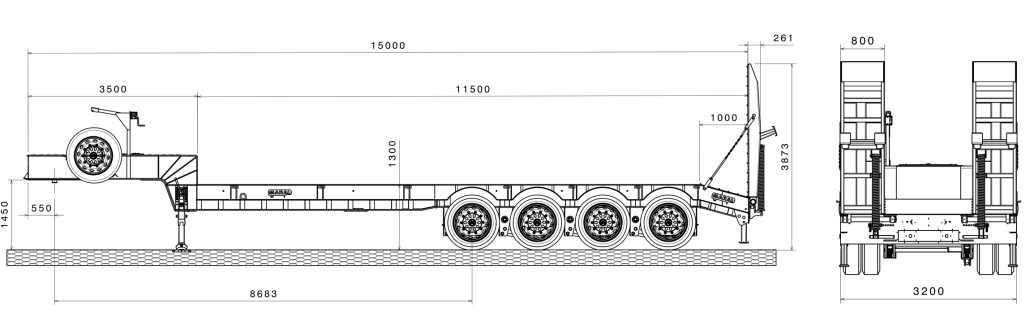

MRL TLB - lowbed

MARAL LOWBED SEMI TRAILERS

Lowboy Trailer: The Professional Solution for Transporting Heavy and Oversized Loads

Lowboy trailers are the primary and ideal solution for transporting heavy, bulky, and indivisible loads. With their unique design featuring an extremely low-profile deck, these trailers can easily move equipment and machinery such as loaders, bulldozers, cranes, excavators, and large transformers. If you work in the transportation, road construction, mining, or oil and gas industries, a lowboy trailer is one of your most important tools.

Advantages of Using a Lowboy Trailer

- High Stability and Safety: The low deck design brings the cargo's center of gravity closer to the ground. This feature significantly reduces the risk of tipping and makes transporting heavy and sensitive loads much safer.

- Transporting High-Profile Loads: The trailer's low height allows for easy passage under bridges and through tunnels, eliminating many route limitations.

- Flexibility and Efficiency: The adjustable axles help with optimal weight distribution and make loading and unloading various loads easier.

- Reduced Road Strain: An advanced suspension system distributes the cargo's weight evenly, preventing damage to the asphalt and road infrastructure.

- Ease of Loading and Unloading: The low deck height makes it simple and quick to load heavy machinery without needing additional equipment. This leads to reduced operational time and costs.

Maral Sanat: A Leader in Quality Lowboy Trailer Manufacturing

Maral Sanat Javid is a well-known and reputable brand in the trailer manufacturing industry in Iran. Utilizing modern technology and international standards, the company produces and supplies various high-quality lowboy trailers. Maral Sanat's products are a reliable choice for transportation businesses due to their high durability, engineered design, and use of quality components.

Maral Sanat's lowboy trailers meet diverse customer needs with the following features:

- Robust Chassis: The chassis, made from high-strength steels, ensures the ability to carry heavy loads.

- Advanced Suspension System: The use of high-quality air or spring suspension provides a smoother and safer ride.

- Reliable Braking System: Equipped with ABS/EBS braking systems for better control in various road conditions.

- Powerful Axles: Axles from reputable international brands like SAF or BPW.

For purchasing and more information about lowboy trailers and other Maral Sanat products, you can visit the company's official website.

A Guide to Optimizing the Use of a Maral Lowboy Trailer

Optimizing the use of a lowboy trailer not only helps increase its safety and lifespan but also reduces costs and boosts the efficiency of your transportation operations. This process involves several key steps that must be considered from before the journey to after the cargo is unloaded.

Detailed Planning Before Loading

- Cargo Identification: First, accurately calculate the weight, dimensions, and center of gravity of the load. This information helps you choose the right type of lowboy trailer and the necessary number of axles.

- Route Analysis: The transport route must be checked for bridge heights, tunnels, road width, and inclines. This step is especially crucial given the low height of the lowboy trailer.

- Required Permits: Ensure you have obtained all necessary permits for transporting oversized loads from the relevant authorities.

Proper and Safe Loading

- Weight Distribution: The load should be placed on the deck in a way that its weight is distributed evenly across the axles. Centering the load on the trailer prevents excessive pressure on a single point.

- Using Ramps: Use appropriate ramps for loading mobile machinery like loaders or excavators. Many lowboy trailers, such as those from Maral Sanat, are equipped with hydraulic or mechanical ramps that simplify this process.

- Securing the Load: Securely fasten the load to the trailer deck using chains, steel cables, or special straps. Use the trailer's standard and sturdy anchor points for this purpose to prevent the load from shifting during transit.

Regular Maintenance and Inspection

- Daily Inspection: Before each use, carefully inspect the trailer's condition, including the tires, braking system (ABS and EBS), suspension, and connections.

- Scheduled Servicing: Lubricate moving parts, check the hydraulic system (if applicable), and adjust tire pressure according to the scheduled maintenance plan. Proper maintenance helps extend the lifespan of components and reduce repair costs.

Final Thoughts

Choosing the right tool for transporting oversized loads is a critical decision. With its unmatched stability, ability to carry high-profile cargo, and ease of loading and unloading, the lowboy trailer has earned a key position in the industry as a professional and safe solution.

For purchasing this product and receiving more comprehensive guidance, contact our consultants.