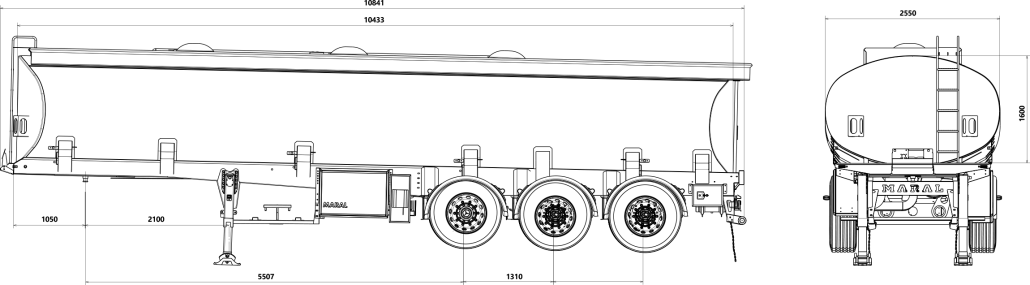

MRL TK3 - fuel tanker

MARAL 3 AXLES FUEL TANKER SEMI TRAILER

Fuel Tanker Semi-Trailer: A Three-Axle Solution for Safe and Efficient Transport

The three-axle fuel tanker semi-trailer is an essential vehicle in the petroleum and fuel transportation industry. With their specialized design, these trailers play a crucial role in the safe and efficient delivery of petroleum products from refineries to distribution centers, gas stations, and industrial facilities. Due to the flammable and hazardous nature of their cargo, these tankers are designed and built to extremely strict safety standards. The three-axle configuration not only increases carrying capacity but also ensures stability and safety on long and uneven roads.

What is a Fuel Tanker Semi-Trailer and How is it Used?

A fuel tanker semi-trailer is a specialized trailer designed to transport flammable liquids and petroleum products such as gasoline, diesel, and crude oil. The body of these tankers is typically constructed from carbon steel or stainless steel and features internal partitions (multi-compartment tanks) to optimize weight distribution and enhance safety during transport.

The three-axle tanker is a popular choice for long-distance and intercity or international transport due to its ability to carry a larger volume and weight. The main applications of these trailers include:

- Transporting fuel from refineries to distribution stations.

- Supplying fuel to industrial centers and factories.

- Transporting aviation fuel.

- Distributing fuel to power plants and electricity generation centers.

Key Features and Advantages of a Three-Axle Fuel Tanker

Built with advanced technology and adherence to global standards, the three-axle fuel tanker offers several competitive advantages:

- Exceptional Safety: These tankers are equipped with advanced safety systems such as emergency discharge valves, anti-rollover systems (RSP), and electronic braking systems (EBS). The multi-compartment tank design prevents the sudden shifting of liquid, which helps maintain the trailer's balance. High-quality, standard valves also play a vital role in precise flow control and preventing leaks during loading and unloading.

- Increased Carrying Capacity: The three-axle design significantly increases the legal carrying capacity of the trailer, making it suitable for transporting large volumes of fuel. This reduces the number of trips required and, consequently, lowers transportation costs.

- Enhanced Stability: The three axles distribute the tanker's weight more effectively, increasing its stability, especially on sharp turns and slippery roads.

- Durable Body Material: The tanker body is made from high-quality ST52-3 carbon steel or 304 stainless steel alloys, which offer excellent resistance to corrosion, impact, and internal pressure.

- Safe Walkway and Platform: The walkway and platform on the tanker are made of anti-slip aluminum sheeting, ensuring the safety of personnel during inspections or loading/unloading operations.

- Rear Bumper and Parking Lock: A fixed rear bumper acts as a protective layer, and the parking lock prevents the trailer from unintended movement when parked.

- Essential Accessories: Three-axle tankers are equipped with a spare tire holder, providing drivers with added security on the road.

Important Considerations When Choosing a Fuel Tanker

Purchasing a three-axle fuel tanker is a significant investment. Keeping the following points in mind will help you make the best choice:

- Body Type and Material: Ensure the tanker body is constructed from high-quality steel with standard certifications. Stainless steel is a better option for transporting various fuels and chemicals.

- Standards and Certifications: Verify that the trailer has valid domestic and international certifications. These certifications guarantee the product's safety and quality.

- Safety Systems: Make sure the trailer is equipped with essential safety systems such as underground discharge valves, EBS braking systems, and anti-rollover systems.

- Compartments and Capacity: Choose the number of compartments and overall capacity based on the type and volume of cargo you plan to transport.

- Brand and After-Sales Service: It's crucial to buy from reputable and well-known brands that offer after-sales service, warranties, and access to spare parts.

How to Optimize the Use of a Three-Axle Fuel Tanker

Optimizing the use of a three-axle fuel tanker goes beyond simple driving. It depends on strict adherence to safety principles, proper cargo management, and regular maintenance. By following these tips, you can ensure maximum efficiency and safety in your fuel transportation operations.

1. Loading, Cargo Management, and Safety Securing

- Correct Loading: Always perform loading and unloading operations in designated areas and in full compliance with safety protocols. Ensure all valves and connections are secure to prevent any leaks.

- Cargo Management: Due to the tanker's multi-compartment design, distribute the liquid's weight correctly. Filling the compartments fully or nearly fully prevents severe liquid shifting on turns and during braking, which increases the trailer's stability.

- Safety at Stops: When stopping, always use the parking lock to prevent the trailer from moving unintentionally.

2. Safe and Stable Driving

- Awareness of Weight Shifts: When driving, always remember that the liquids are in motion. For this reason, drive with extra caution on turns and uneven surfaces. The three axles enhance stability, but caution is always the top priority.

- Using Safety Equipment: Learn how to use advanced braking systems like EBS correctly. These systems can significantly help prevent accidents in emergency situations.

Final Thoughts

A three-axle fuel tanker semi-trailer is more than just a vehicle; it's an investment in the future of your business. By combining safety, durability, and efficiency, this product ensures the secure and optimal transport of fuel. If you're looking to purchase a reliable product that can meet your transportation needs in the best possible way, the three-axle fuel tanker is the perfect choice.

For more information on the price of fuel tankers, specialized consultations, and to learn more about available options, contact our experts now.