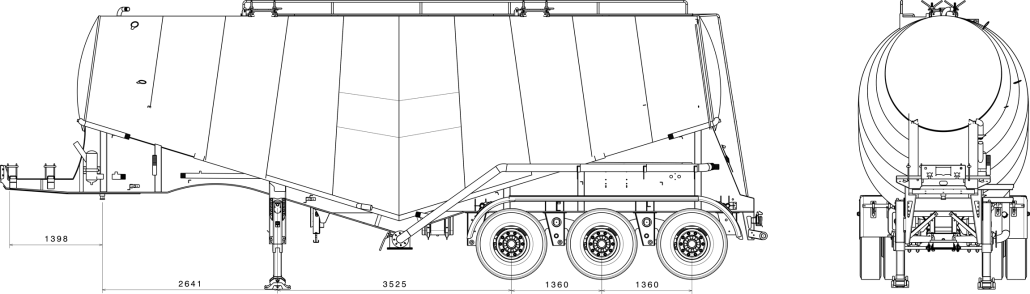

MRL BN3 - bulker

Boost your bulk transport efficiency with our 3-axle cement bulk trailer. Featuring a robust steel design, twin tires for superior stability, and a fast discharge system for a reliable and safe delivery of powdered materials.

3-Axle Cement Bulk Trailer (Twin Tires): Innovation in Powdered Material Transport

The 3-axle cement bulk trailer from Maral Sanat is an engineered response to the key needs of the construction industry. With its robust structure and advanced systems, it ensures the safe and hygienic transportation of powdered materials. From cement and lime to other powdered construction materials, this bulk trailer, with its high capacity and flawless performance, has become an essential tool for civil engineering projects.

Why a Cement Bulk Trailer is a Competitive Advantage

In the world of construction, speed and efficiency in the supply chain are paramount. A high-quality bulk trailer not only accelerates the transport process but also prevents cargo waste and contamination. The cement trailer, with its durable steel tank and a pressurized discharge system, allows for quick and seamless cement unloading. This feature eliminates the need for manual handling and reduces operational costs. With their exceptional road stability, these trailers are a smart choice for transporting raw materials to remote and difficult-to-access project sites.

Advantages of the 3-Axle Cement Bulk Trailer (Twin Tires)

Using the Maral 3-axle cement bulk trailer with twin tires offers significant advantages for businesses in the construction and bulk material transport industries:

- Increased Payload Capacity: The 3-axle structure allows for a larger volume of cement to be carried per trip. This directly leads to increased productivity and reduced transport costs.

- Greater Stability and Safety: The use of a triple axle and twin tires creates a larger contact surface with the road. This feature contributes to better trailer stability, especially on bends and uneven roads, and minimizes the risk of overturning.

- Fast and Complete Unloading: Equipped with a powerful diesel engine and air compressor, this bulk trailer can discharge its cargo in the shortest possible time. This advanced system leaves no residue in the tank, saving both time and material.

- High Durability and Longevity: High-quality manufacturing and the use of premium materials, along with precise technical tests (such as a 2-bar pressure test and weld inspection), guarantee the bulk trailer's resistance to wear and corrosion, significantly increasing its useful life.

Applications of the 3-Axle Cement Bulk Trailer

The 3-axle cement bulk trailer with twin tires is designed for a wide range of activities in the construction and bulk logistics industries. Its main applications include:

- Cement Transport: The primary use of this trailer is to transport large volumes of cement from production plants to construction projects, ready-mix concrete factories, and distribution warehouses.

- Bulk Powdered Material Hauling: In addition to cement, this bulk trailer is also suitable for transporting other powdered bulk materials like lime powder, stone powder, fly ash, and similar substances.

- Large-Scale Construction Projects: These trailers are essential tools for supplying raw materials to major construction projects such as dam building, bridge construction, and road-building.

- Logistics Services: Specialized transport companies that handle bulk material logistics use these bulk trailers as a key part of their fleet.

Overall, this bulk trailer, by combining durability, safety, and efficiency, is a comprehensive solution for any business looking to optimize its bulk material transport processes. If you need to transport dry and granular bulk materials using other methods, you can also consider other Maral Sanat products, such as the dump trailer.

Final Word

Quality and reliability are two elements that build a lasting investment for you. The Maral Sanat bulk trailer, committed to these principles, offers a product that not only guarantees efficiency and safety but also plays a role as a reliable investment in the sustainable progress of your company.

To purchase a cement bulk trailer and get more information on its price, our expert team is ready to answer your questions. Simply contact our sales consultants.