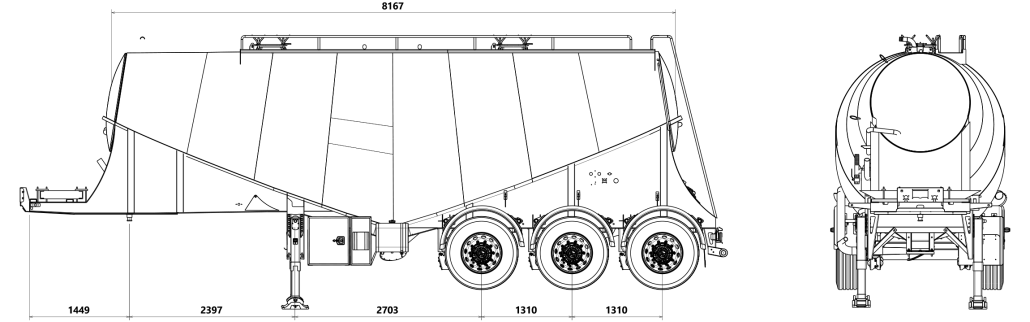

MRL BN3 - bulker

A 3-axle cement bulk trailer is a robust solution for transporting powdered materials like cement. Its high-capacity design, combined with advanced safety features and a fast pneumatic discharge system, makes it a highly efficient and reliable choice for the construction and logistics industries.

3-Axle Cement Bulk Trailer: Power and Safety in Powdered Material Transport

The 3-axle cement bulk trailer is a reliable and efficient solution for transporting powdered materials. With a precise engineering design and the use of high-quality raw materials, this product has successfully met the needs of the construction and manufacturing industries. With Maral Sanat's bulk trailers, you can be completely confident in the safe and rapid movement of your cargo, even under challenging road conditions.

Why a 3-Axle Bulk Trailer Is an Essential Choice

In the construction and manufacturing industries, the speed and accuracy of raw material transport play a vital role. A high-quality bulk trailer not only makes the loading and unloading process easy and fast but also prevents cargo waste and contamination. These trailers, due to their durable tank structure and advanced discharge system, allow for the transport of large volumes of powdered materials with minimal human intervention. This feature is particularly important in large-scale construction projects that require a continuous supply of raw materials. For transporting oil and chemical substances, you can also use Maral Sanat's fuel tanker and bitumen tanker.

Advantages of Using a Cement Bulk Trailer

The advantages of using a 3-axle cement bulk trailer include:

- Increased Productivity and Reduced Costs

- High Payload Capacity: These bulk trailers have a higher carrying capacity due to their three axles. This allows you to transport a larger volume of cement per trip, ultimately reducing the number of trips required and saving time, fuel, and labor costs.

- Fast and Easy Unloading: The pneumatic (compressed air) discharge system allows you to unload the cargo in the shortest possible time and without the need for extensive manual labor. This reduces downtime at the project site and increases productivity.

Enhanced Safety and Quality

- Preservation of Cement Quality: The completely sealed tank prevents moisture, dust, and contamination from entering the cement. This ensures that the cement reaches the end-user with its original quality.

- Transport Safety: The 3-axle design and the use of advanced braking systems like EBS and RSP increase the trailer's stability and control on the road. This significantly reduces the risk of rollovers, especially on winding roads and in adverse weather conditions.

- Dust-Free Unloading: The pneumatic discharge system prevents cement dust from spreading into the air. This benefit is not only environmentally friendly but also good for the health of workers and others present on-site.

High Durability and Longevity

- Quality Material Construction: The body of these bulk trailers is made from durable, standard-compliant steel, which provides high resistance against pressure, impact, and harsh environmental conditions.

- Strict Quality Control: The production process is under strict supervision and includes certified weld inspections and pressure tests. These precise quality controls guarantee the bulk trailer's strength and long service life.

How to Use a Cement Bulk Trailer Optimally

Optimal use of a 3-axle cement bulk trailer is not limited to transporting cargo. It requires adherence to a set of operational and maintenance practices to ensure maximum efficiency, safety, and a long service life for the product. If you are looking for different types of trailers for other purposes, Maral Sanat offers a variety of options.

Regular Maintenance and Inspection

Optimizing the use of these bulk trailers begins with proper maintenance.

- Continuous Technical Inspection: Periodically check vital systems such as the brakes, suspension system, tire pressure, and the pneumatic system (compressor and valves). Ensure that hoses, couplings, and the air tank are in perfect condition to avoid issues during cargo unloading.

- Regular Cleaning: After each discharge, clean the tank of any cement residue. The accumulation of cement inside the tank can cause valve blockages and reduce discharge efficiency.

Proper Loading and Unloading

Following proper loading and unloading procedures helps with both safety and efficiency.

- Appropriate Loading: When loading, ensure the cargo is distributed evenly and balanced inside the tank. Unbalanced loading can cause extra stress on the axles and suspension system.

- Correct Use of the Pneumatic System: Use the appropriate air pressure for unloading. Excessive pressure can damage the equipment, while low pressure leads to slow and inefficient discharge.

- Use of the Front Axle Lift: When the trailer is empty, use the automatic front axle lift to raise the axle. This helps reduce tire wear and fuel consumption.

Optimal Driving

Driving these trailers, due to their heavy weight, requires skill and precision.

- Adhere to the Speed Limit: Avoid excessive speed, especially on bends and downslopes. The heavy weight of the bulk trailer increases the braking distance.

- Correct Gear Use: On sloped roads, use lower gears to prevent excessive strain on the brakes.

Final Word

In conclusion, the 3-axle cement bulk trailer, as a modern and efficient solution, has revolutionized the bulk material transport process. This specialized vehicle, by combining power, safety, and efficiency, plays an irreplaceable role in advancing civil engineering projects and stands as a symbol of progress and technology in the heavy transport industry.

To learn about the price of a cement bulk trailer and receive expert consultation, contact our consultants.