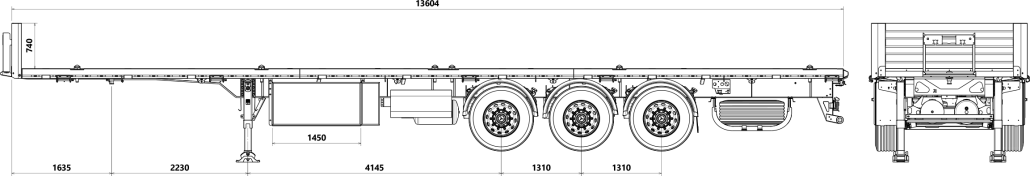

MRL 385 - flatbed

MARAL 3 AXLES FLATBED SEMI TRAILER

Maral 3-Axle Flatbed Trailer: The Backbone of Heavy Haulage

When it comes to transporting heavy and oversized goods, a simple, reliable solution is often the best. The Maral 3-axle flatbed trailer is designed to be just that—a robust and highly versatile workhorse. Its open design and three-axle configuration make it the go-to choice for a wide range of industries, providing exceptional stability and a high payload capacity for long-distance hauls.

Why Choose a Flatbed Trailer?

A flatbed trailer is essentially a mobile, flat platform with no walls or roof. This straightforward design is what gives it unparalleled flexibility. It allows for quick and easy loading and unloading from all sides using cranes or forklifts, which is perfect for cargo with unusual shapes or dimensions that wouldn’t fit in an enclosed trailer.

This type of trailer is a popular choice for:

- Construction: Hauling everything from steel beams and rebar to large pipes and precast concrete sections.

- Heavy Machinery: Moving excavators, loaders, and other large industrial equipment.

- Logistics: Transporting containers, oversized pallets, and other bulky items.

Standard vs. Roll-On/Roll-Off: Tailored to Your Needs

Maral offers two primary versions of the 3-axle flatbed, each built for a specific job:

- Standard Flatbed: This is the traditional model with a smooth, flat deck. It’s ideal for most heavy hauling tasks where cargo can be lifted directly onto the trailer.

- Roll-On/Roll-Off (RoRo) Flatbed: This specialized trailer features a built-in roller system. It's an excellent solution for port operations and terminals where wheeled cargo, like containers with dollies, can be effortlessly rolled on and off the deck, saving significant time and effort. This model is often custom-built to meet a client's specific operational needs.

Built for Durability, Designed for Safety

Choosing a Maral trailer means investing in a product built to the highest standards. Our trailers are not only durable but also packed with features that ensure a safe journey for both the driver and the cargo.

- High-Quality Construction: Every trailer undergoes rigorous hydraulic testing and certified welding inspections to guarantee the structural integrity of the chassis and body.

- Enhanced Stability: The 3-axle design provides superior weight distribution, allowing the trailer to handle heavy loads with incredible stability, even on challenging roads.

- Advanced Safety Systems: We equip our trailers with essential safety features like an EBS (Electronic Braking System) and container locks to secure your load.

- Automatic Axle Lifter: This smart feature automatically lifts the front axle when the trailer is empty, which helps reduce tire wear and improves fuel efficiency.

- Secure Lashing Points: The deck is equipped with 9 ratchets and side hooks to firmly secure your cargo with chains or straps, preventing any movement during transit.

- Ship Lashing Hooks: For sea transport, specific hooks are included to secure the trailer on a ship's deck, highlighting its versatility.

Getting the Most Out of Your Trailer

To ensure maximum efficiency and safety, remember to:

- Distribute the load evenly across the three axles to maintain stability and prevent excessive stress on any one point.

- Properly secure all cargo using the provided ratchets and hooks. This step is non-negotiable for road safety.

- Perform regular checks on the chassis, deck, and lashing equipment to keep the trailer in top condition.

Conclusion

The Maral 3-axle flatbed trailer is more than just a piece of equipment; it’s a reliable partner for your heavy hauling business. Its simple, effective design and built-in safety features make it a smart investment for anyone looking to transport large or heavy goods efficiently.

For other transport needs, remember to explore our range of high-quality products, such as our tanker trailers for liquids or dump trucks for bulk materials.

If you have questions or would like to discuss a custom solution, our team of experts is ready to help. You can find our contact information on the Contact Us page.